| Sign In | Join Free | My xxjcy.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My xxjcy.com |

|

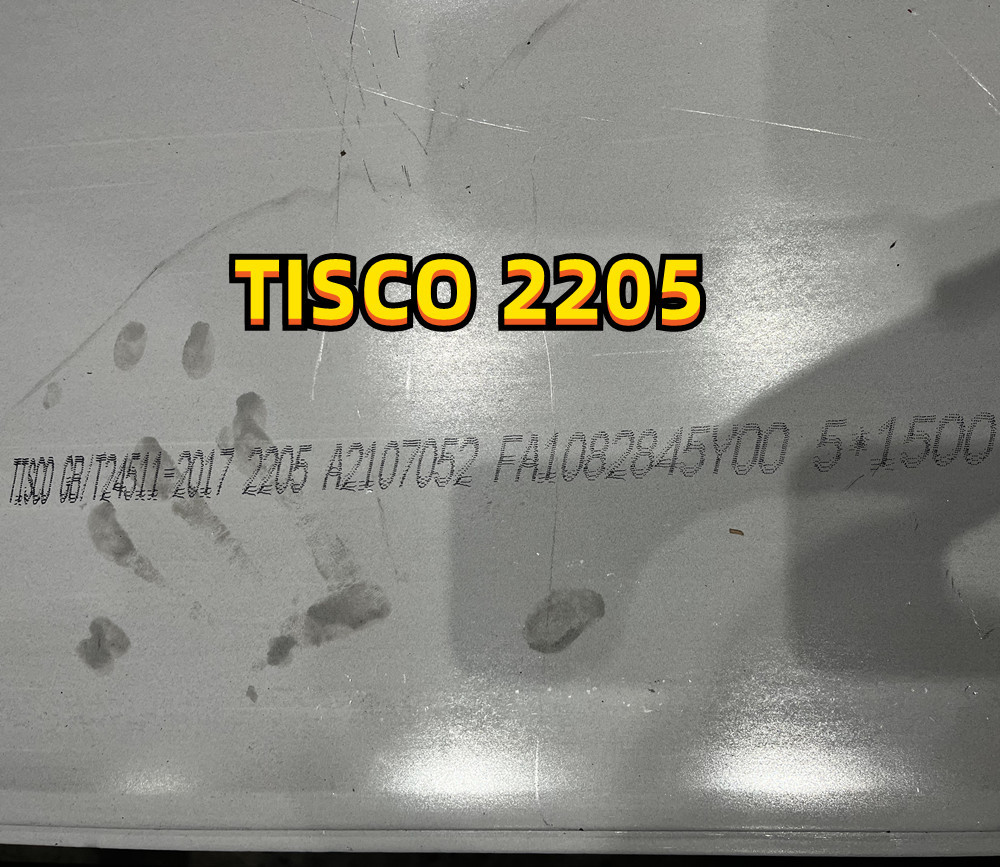

Brand Name : TISCO,BAO STEEL ,JIU STEEL

Model Number : S31803/S32205 2205

Certification : ISO,BV

Place of Origin : China

MOQ : 1 ton

Price : USD 3500-8500/TON

Payment Terms : L/C, T/T

Supply Ability : 2500 Tons

Packaging Details : export packing

Delivery Time : 7 Working Days

Material : Duplex S31803 2205 S32205

Standards : ASME SA240

Width : 1000-2000mm

Length : 2000-6000mm

Cutting : Laser Or Water Cutting

ASTM A 240 : 650min

| C | Cr | Ni | Mo | N | Others |

| 0.020 | 22.1 | 5.6 | 3.1 | 0.18 | S=0.001 |

| PREN = [Cr%] = 3.3 [Mo%] = 16 [N%] ≥ 34 | |||||

| | ASTM A 240 | Typical |

| Yield Strength 0.2%, ksi | 65 min. | 74 |

| Tensile Strength, ksi | 90 min. | 105 |

| Elongation % | 25 min. | 30 |

| Hardness HB | 293 max. | 256 |

| Temperature °F | 122 | 212 | 392 | 572 |

| Yield Strength (0.2%), ksi | 60 | 52 | 45 | 41 |

| Tensile Strength, ksi | 96 | 90 | 83 | 81 |

| Temperature °F | | 68 | 212 | 392 | 572 |

| Density | lb/in3 | 0.278 | -- | -- | -- |

| Modulus of Elasticity | psi x 106 | 27.6 | 26.1 | 25.4 | 24.9 |

| Linear Expansion (681T4F-T) | 10-6/°F | -- | 7.5 | 7.8 | 8.1 |

| Thermal Conductivity | Btu/h ft. °F | 8.7 | 9.2 | 9.8 | 10.4 |

| Heat Capacity | Btu/lb/°F | 0.112 | 0.119 | 0.127 | 0.134 |

| Electrical Resistivity | in x 10-6 | 33.5 | 35.4 | 37.4 | 39.4 |

|

|

Stainless Steel Plate 2205 Duplex Steel Plate ASME SA240 S32205 , S31803 Duplex Steel 2205 Plate Images |